EFICAD SWOOD 2023 SP0.0 for SolidWorks (x64)

Free Download EFICAD SWOOD 2023 SP0.0 | 1.8 Gb

Owner:EFICAD

Product Name:SWOOD

Version:2023 SP0 for SolidWorks

Supported Architectures:x64

Website Home Page :

https://swood.eficad.com/

Languages Supported:english

System Requirements:Windows *

Size:1.8 Gb

The EFICAD development team is pleased to announce the availability ofEFICAD SWOOD 2023 SP0is the latest iteration of the iconic design and manufacturing software for woodworking professionals, such as fitting, furniture, and construction companies.

Introducing SWOOD 2023: The Latest Design and Manufacturing Software for Woodworkers

This new version includes many new features and improvements that greatly facilitate its use. Indeed, our developers have extended the wood project design and manufacturing scope to a higher level while staying true to its parametric and "intelligent" software. The exclusive features of SWOOD allow companies to save valuable time through increasingly tailored automation for their projects.

Save time and increase efficiency with SWOOD Design updates.

SWOOD Design, the parametric design software dedicated to the woodworking industry, has been added with many new features in 2023.

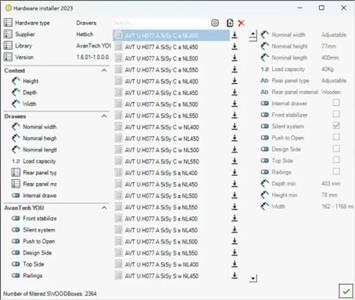

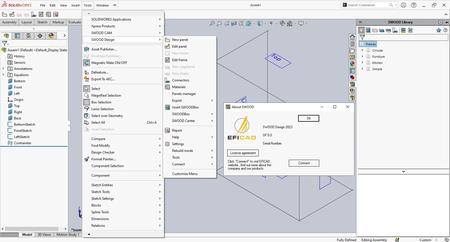

1. Customizable wood projects with SWOOD Design Hardware Installer

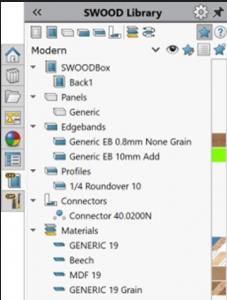

SWOOD Design allows its users to customize their wood projects quickly. One of the flagship elements of the new version is undoubtedly its library, which provides access to a significant amount of materials, boxes, connections, SWOODBoxes, etc. The user can customize library elements and create new ones to meet their needs better.

A complete SWOOD Design library is downloadable during the software installation: the "SWOODData" established by the SWOOD technical team. The goal is to offer suitable and sufficient content while limiting the necessary space for downloading this library. With the introduction of the Hardware Installer in SWOOD Design 2023, users can now search for downloadable content based on precise technical parameters and install it directly into the library with just one click. This feature saves time and makes accessing suitable and sufficient content for woodworking projects more accessible.

Hardware Installer has no limit and offers thousands of library elements that are already available. This dynamic feature can be updated to improve its performance. The EFICAD team is dedicated to continuously creating new content for the library, ensuring that users’ needs are always met. As a result, users can gradually enhance their SWOOD Design library using the Hardware Installer, adding only the necessary elements.

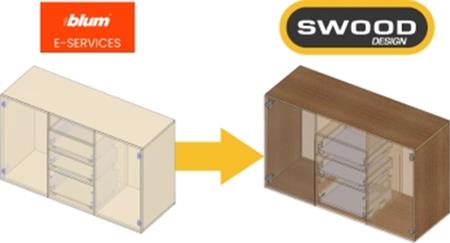

2. Streamline your design process with SWOOD Connect

Linked to the previous innovation, SWOOD Connect was created to improve the download of external content. SWOOD Connect consists of two tools in one:

A. Blum Import lets you import furniture elements directly into SWOOD Design from the "Blum e-service" portal. Blum Import allows you to specify which SWOOD Design materials you want to assign, whether you need a single product or a complete piece of furniture. You can trigger the conversion procedure with a single validation to get an entire SolidWorks assembly, including panels and hardware.

a. ProductionManager (referring to the "digital order folder") is an online service offered by HOMAG. With this feature, it is possible to transfer any SWOOD Design project directly to the HOMAG ProductionManager with all the project-related information.

Simply connect to the external service using your credentials and specify the project data (delivery date, address, etc.). You can automatically transfer production data to the online service with a single click.

With SWOOD Connect, you can streamline your design by connecting industry software. Say goodbye to the tedious process of manually importing and exporting data between different platforms. Take advantage of these powerful tools and optimize your design process today!

3. Enhance your design capabilities with SWOOD Design: Favourites

The new "Favorites" feature in SWOOD Design is a game-changer for woodworking professionals! With its complete and customizable libraries, SWOOD Design offers users many resources. And now, the "Favorites" library takes it to the next level by allowing users to centralize multiple elements (SWOOD Boxes, cabinets, connectors, materials, etc.) in one convenient location easily.

By intelligently aggregating elements from all other libraries, the "Favorites" feature simplifies the search for specific elements, making it easier to find what you need. And with the ability to create multiple categories of favorites, you can quickly locate the elements you need for different projects. For example, imagine a custom furniture fitting company that wants to define several ranges of custom-made furniture. They can create as many categories of favorites as they have ranges and insert all the elements applied to these ranges. This allows them to find the specific elements quickly and easily for each project without confusion.

Overall, the "Favorites" feature is an incredibly powerful tool for woodworking professionals, allowing them to save time and work more efficiently.

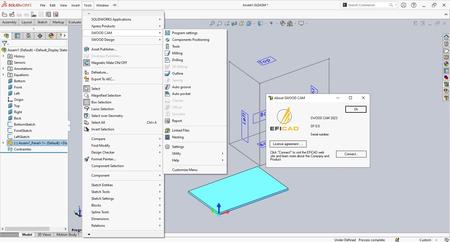

Upgrade Your CNC Machining Operations with SWOOD CAM’s New Features

SWOOD CAM, a specialized software for programming wood machining projects, also offers new features in its 2023 version.

1. "Roughing" algorithm for complex 3D shapes machining

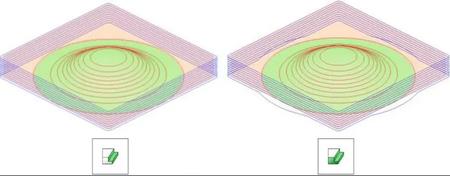

SWOOD CAM’s "Roughing" operation is one of two operations, alongside the "Finishing" operation, that enable the machining of complex 3D shapes. This initial operation effectively eliminates material between the raw volume and the final piece, resulting in only a thin layer of material to be machined during the "Finishing" operation.

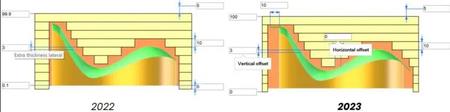

In its 2023 version, SWOOD CAM has enhanced the "Roughing" operation and introduced new machining parameters through an optimized interface. Notably, the "Lateral Allowance" parameter has been replaced by two parameters, "Vertical Offset" and "Horizontal Offset," providing more precise operation adjustment.

The operation has been optimized aesthetically and functionally to be more efficient with complex shapes. Among these modifications, the operation now features three new unique and exciting parameters for 3D volume machining:

– "Overlap strategy": allows adding a contour pass to the finished volume operation, thereby increasing the quality of the finished piece, even at the roughing stage

– The "Precision" feature permits users to fine-tune the algorithm’s accuracy to balance precisely detecting the reference volume and reasonable calculation time. It is essential to customize this parameter based on the piece’s size and complexity that needs to be machined.

a. "Machining zone": probably the most interesting of the three because it offers several options for defining the shape of the piece to be machined:

. The first option is the shape of the stock of the piece, i.e., the parallelepiped that encloses the piece and is parallel to the machining axes.

. The second option allows choosing any volumetric body in the SOLIDWORKS FeatureManager creation tree.

. Finally, the third option allows selecting any sketch from the SOLIDWORKS FeatureManager creation tree.

The last two options significantly increase versatility by restricting the operation to machining a well-defined portion of the volume. This way, it is possible to rough out only a part of the piece with certain machining conditions and then rough out the rest with other machining conditions. Thus, the "roughing" operation is optimized for more complex shapes while offering flexibility.

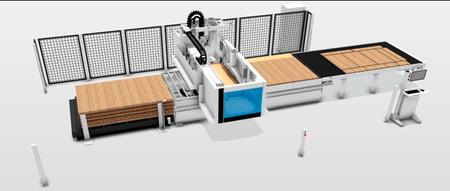

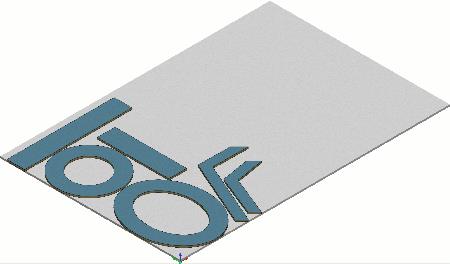

2. SWOOD CAM’s innovative "Cutting Scrap" operation for CNC nesting machines

Companies that use Nesting machines are always looking for ways to improve their industrial processes and make them faster and more efficient. One way to achieve this is by adding automation and production flow optimization features such as automatic panel loaders and conveyors. Some companies even go as far as installing robotic arms to sort the machined parts.

However, waste management from nesting can be problematic due to the irregular size and shape of the leftover scrap pieces. To address this challenge, SWOOD CAM has developed a new "Cutting Scrap" operation allowing for machining programming considering scrap pieces. This standardizes scrap size and makes automatic collection by the conveyor more efficient.

SWOOD Nesting 2023: New Features for Woodworking Professionals

SWOOD Nesting is an advanced add-on for SWOOD CAM explicitly designed for woodworking professionals. It provides access to a robust nesting algorithm that arranges parts on panels to minimize material waste and optimize production efficiency. With the latest version, SWOOD Nesting 2023, several new features will help woodworking professionals take their productivity to the next level.

Enhanced labelling functionality for precision and efficiency

The software offers numerous additional functionalities, but here is an example from the 2023 version: adding an automatic labeling functionality for pieces. In SWOOD Nesting 2022, this function allowed specific recent Nesting machines to apply the labels of the pieces on the plate autonomously, before machining, with a configurable orientation of 0 or 90°.

With the 2023 version of SWOOD Nesting, it is now possible to individually reorient the labels. Where the global orientation is not necessarily relevant for specific pieces that have been nested (horizontal labels with vertical pieces that are pretty thin), the user can choose the orientation of the labels after the nesting process.

Inter-Software Integration with SWOOD 2023

All SWOOD Design, SWOOD CAM, and SWOOD Nesting software are interconnected, allowing users to manage their wood projects with great fluidity. SWOOD 2023 is no exception, offering new features that impact all software in the SWOOD portfolio.

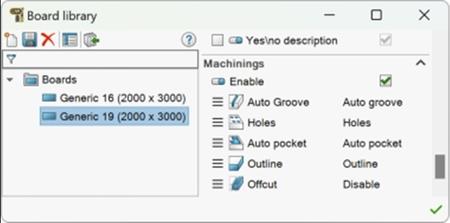

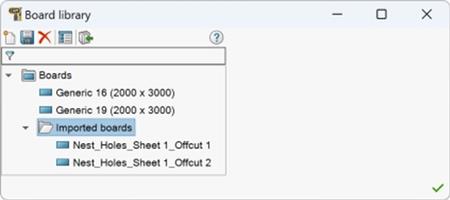

1. Automatic insertion of machining entities from nesting panels

The first significant innovation that spans SWOOD Nesting and SWOOD CAM software relates to integrating machining entities into the Nesting assembly. The 2022 version of SWOOD Nesting allowed users to streamline their workflow by integrating machining entities into the assembly, reducing repetitive tasks. The 2023 version builds on this feature by offering greater flexibility regarding which machining operations are integrated for each plate. Users can ensure that each Nesting result contains a complete machining phase by configuring the settings in the Nesting plate library.

This feature is very advantageous for companies that use various materials in their nesting. Indeed, some materials require special attention to avoid damage, and their machining must be programmed accordingly. Users can even combine both insertion features: automatic global insertion of machining, with the 2022 feature, combined with personalized insertion of machining, only for "sensitive" panels, with the 2023 feature.

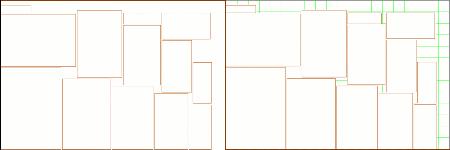

2. Management of reusable nesting offcuts

Woodworking professionals will find the second inter-software innovation of SWOOD 2023 particularly intriguing. This new feature set includes SWOOD Nesting, SWOOD CAM, and the SWOOD Report, allowing for the efficient use of leftover materials. Some panels may not need to be fully utilized when creating nested parts using SWOOD Nesting, creating excess material. With SWOOD 2023, users can now quickly identify the leftover material that can be reused in future nesting projects, thus reducing waste and saving resources. That is why the developers have created a set of innovative features allowing the valorization of Nesting offcuts:

– The first feature, "Reusable Offcuts," is integrated into SWOOD Nesting and allows enabling or disabling the creation of reusable offcuts based on the unused space on the nesting panels.

The user can specify, using different parameters, the maximum number of reusable scraps to create per plate and the minimum size of a scrap to be generated.

– The second feature and new machining entity, "Offcuts," is integrated into SWOOD CAM and automatically detects the presence of reusable scraps in the Nesting assembly. It then presents the user with different ways to machine them (routing or sawing). It is part of the "automatic" machining entities and therefore applies without selection.

Once the operation is chosen, the user can machine the plate’s first or second scrap or both.

This machining entity is available to insert machining entities from Nesting panels automatically.

a. The third feature specific to managing Nesting offcuts, "ProgramOffcuts," is integrated into the SWOOD Report.

Indeed, after validating the programming of the machining for the Nesting assembly, the user can launch a SWOOD Report to initiate production. The new "ProgramOffcuts" feature then generates an XML file containing all the information of the reusable offcuts in the project. What is left to do is to import this file into the plate library and thus define these offcuts as plates to use for a future nesting project.

This combined set of new features creates a complete cycle of reuse of usable offcuts and allows the user to define a relevant and flexible strategy for offcut reuse. Overall, these features are almost autonomous once configured and naturally integrated into the business organization.

SWOODis a comprehensive CAD/CAM software dedicated to the woodworking industries. Developed as an integral part of the SOLIDWORKS ecosystem, SWOOD combines top-of-the-line features to bring your designs to life, streamline your manufacturing workflow, and introduce automation when needed. With SWOOD, you have all the tools to optimize your woodworking projects from start to finish, ensuring precision, efficiency, and unmatched quality.

What´s New SWOOD Design 2023

See the innovations from SWOOD Design 2023 in this video. there are improvements in plate editing, texture display in the library, selection of multiple templates and much more.

Founded in 1989,EFICADbegan its CAD/CAM experience with educational products in mechanical sector. In 1991, SCM company solicited EFICAD to bring a specific CAM solution for one of the first NC router installed in France. Interested in woodworking we started to implement the specific technologies of this sector in our Autocad based CAM. Since that time, EFICAD has helped woodworkers to produce windows, doors, stairs, furniture and many other products and stay in touch with the latest technology like the numerical working table that we manage since 2007.EFICAD and DS SolidWorks have started their partnership in 2001 with EFICNSW, a mechanical CAM software which is now distributed in more than 2000 education sites in France. In 2009 SWOOD joined the SOLIDWORKS solutions offered by EFICAD.

DONWLOAD FROM RAPIDGATOR

uzjnb.SETUP.rar.html

DONWLOAD FROM UPLOADGIG

uzjnb.SETUP.rar

DOWNLOAD FROM NITROFLARE

uzjnb.SETUP.rar